FABRICWOOD PAVILION

COMPLETED

HERMAN MILLER @ XTRA SHOP-IN-SHOP V.2

FUNCTION: Furniture Showroom

SIZE: 845 sqm

LOCATION: SINGAPORE, 6 Raffles Boulevard #02-48 Marina Square, 039594

MATERIAL: OBERFLEX, SYCAMORE PLY

GOLD AWARD

2018 Prix Versailles

—

SHOPS & STORES INTERIOR

SPECIAL PRIZE, SOUTH ASIA & THE PACIFIC

WINNER

2017 WORLD FESTIVAL OF INTERIORS

—

INTERIOR OF THE YEAR

BEST DISPLAY INTERIOR

WINNER

2018 FRAME AWARDS

—

BEST USE OF MATERIAL

—

GOLD AWARD

2016 SINGAPORE INTERIOR DESIGN AWARDS

—

—

RETAIL CATEGORY

The brief was developed by studying Herman Miller’s core body of work - Chairs. Herman Miller’s extensive range of chairs can be broadly categorized into two important families from two different eras – the heritage series, characterized by the Eames’ moulded plywood chairs and the Ergonomic work chairs, widely known for their emphasis on comfort achieved through formal, structural and material innovation to “mould” the chair to the human body. These chairs embody their philosophy, culture and aspirations; a desire to constantly innovate, integrate technology with design and produce high quality, purposeful, human-centred products.

In Version 02, the challenge was to surpass the first version both geometrically and structurally. The problem was twofold. Firstly, to develop a new material system and technique that allows the free-form shaping of plywood that is intuitive and simple. Secondly, to reduce the number of components so as to improve upon the assembly process of the grid shell. The new Herman Miller shop-in-shop is a fabric-like surface that appears to be casually pulled across the entire 8m volume. The rippling on the surface increased the “softness” the plywood making it appear to be stagnant in the wind. The circular cut-outs allowing for tolerance on the surface, along with the cable ties and rivets are signature of this material system expressing its intuitive mechanical workings.

Occupying a 20m long by 7m wide space, the Herman Miller store is expressed as a lightweight plywood minimal surface skin that stretches across the entire site like a sail of tensile fabric. Propped up by a series of arches that frame the entrances and connections to the rest of XTRA, the street and the adjacent café, the structure leads the viewer from the low 3m entrance to the lofty 8m glass curtain wall at the other end.

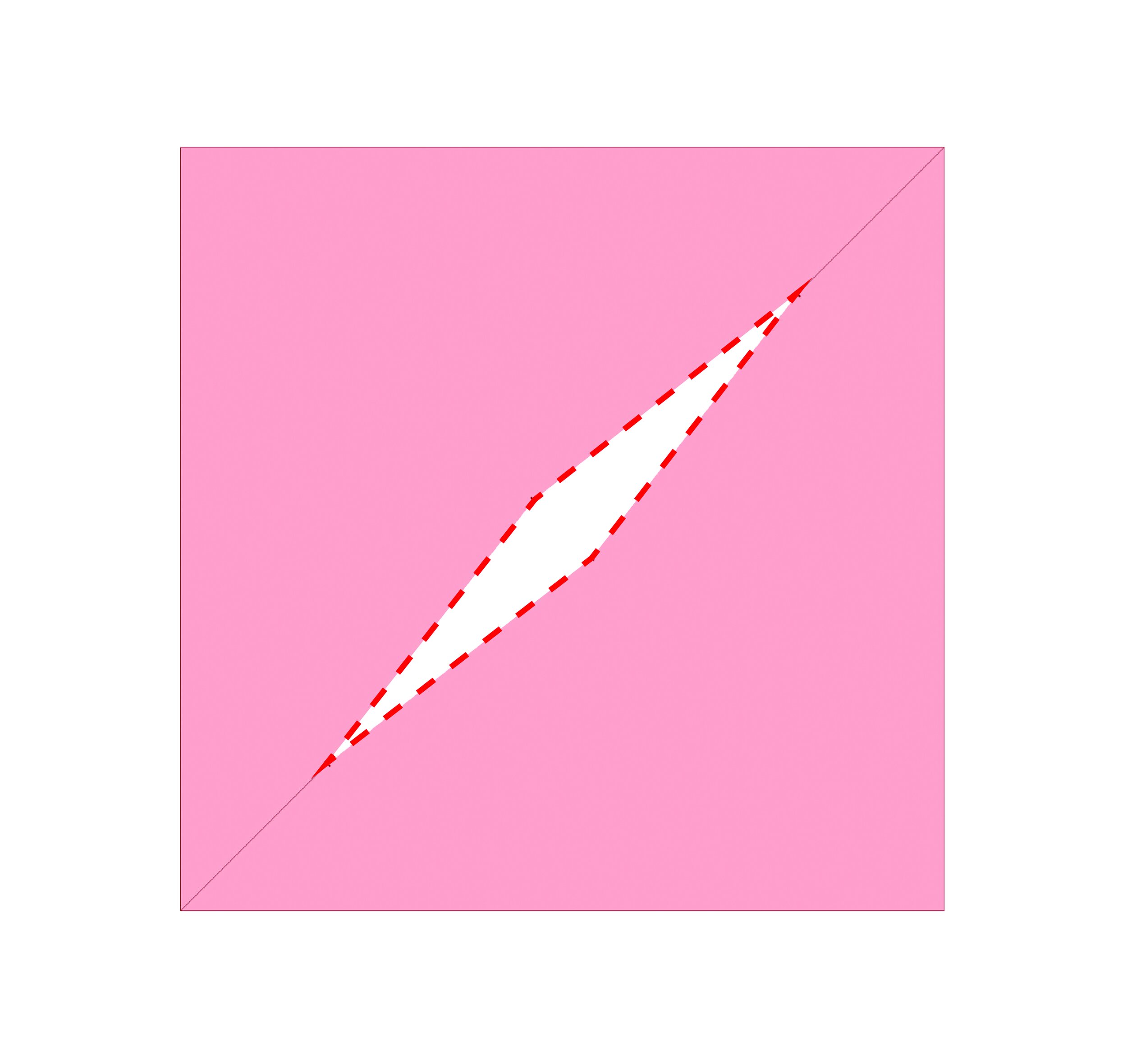

To achieve this, a traditional tailoring technique used for shaping fabric to fit the human body called “darting” was exported onto plywood. A continuous iteration and loop between computation and physical modelling helped to calibrate the darts and their respective angles on a flat piece of plywood which determine its eventual curvature when closed. Circular cut-outs are used at the converging point of the darts to allow the plywood to bend and avoid tears.

Learning from the design processes of Herman Miller’s chairs, the design research was geared towards a material exploration of plywood to form a lightweight plywood envelope that is “moulded” to its host – XTRA. The envelope shall form an independent entity that plugs into the shop space of XTRA that allows visual links yet maintains the unique identity of both parties. Revisiting traditional techniques of shaping timber and plywood reveals that plywood is normally curved in one direction forming “developable surfaces”; geometrically, like a cylinder. To form doubly curved surfaces or “non-developable” surfaces, one has to either restrain the bending and twisting on a rigid frame, such as in traditional boat construction, nicknamed the “tortured ply or timber construction”, or use adhesive and heat treatment to press layers of ply into a stagnant form.

Tortured ply construction will require extensive structural framework and it is too labour intensive while the heat press moulding method would be too costly. Fabricwood is based on the possibility of manipulating flat pieces of plywood to form multi-curvature surfaces. Reminded of Herman Miller’s attempt of shaping an elastic mesh to “mould” against the human body, we looked into the traditional tailoring technique that shapes fabric to the body. Traditional pattern making utilises a method of material subtraction and addition called “darts” to shape the surfaces of fabric. We wanted to test the possibility of shaping large full-sized pieces of plywood using darts – simply by removing material and closing up the slits.

To form darts in plywood, circular holes were created at the apex of the darts to release the stress when the darts are closed, preventing it from cracking at that point. Initial physical tests result in a complex surface consisting of conical convex hulls, saddles and valleys. However, the operation also caused the overall surface to shrink and twist in different directions making the measurement of the edges complicated.

The different geometrical surfaces and its transformation was then simulated digitally using a computation al software and live physics engine . This is to better understand the controlling parameters of the darting operations and more importantly, to be able to measure the transformations. The digital results are then cross - checked with 1:1 scaled physical mode ls to test the limits of deflection against the modular elasticity of different plywood , composition and thicknesses

The process was a reiterative loop between computer simulation and physical modelling to arrive at an accurate approximation of the plywood surface digitally. Finally, we were able to plot the graph of the relationship between dart angle and deflection angle. With these parameters, we were able to produce flat patterns consisting of combined darts of varying dart angles with full knowledge of the resultant surface topography when the darts are closed.

Ease of construction is an important criterion for the project. After multiple mock ups, cable ties were selected to “stitch” the darts together while laser - cut plywood connectors and pop rivets are used to stitch separate panels together. Each module consists of 2 surfaces and are propped apart using a custom made male - female dowel connectors, allowing the structure to be more rigid while concealing the rivet ends and the cable ties heads.

The overall ambience is one akin to a bazaar where simple tent canopies are pulled across the street. Alongside the Herman Miller structure, the design for the rest of space in XTRA followed the idea of pop-up stores in a bazaar creating a more approachable and casual atmosphere.

PRODUCTION PROCESS:

1. We tested the possibility of shaping large full-sized pieces of plywood using darts – simply by removing material and closing up the slits. Circular holes were created at the apex of the darts to release the stress when the darts are closed, preventing it from cracking at that point. The simple test results in a complex surfaces consisting of conical convex hulls, saddles and valleys. The operation also caused the overall surface to shrink and twist in different directions making the measurement of the edges complicated.

2. Each panel is laid out and cut from 1.8mm custom made plywood using in-house precision CNC routers.

3. The darts are sewn together using cable ties, after which the top and bottom pieces are connected using spacers in between. The panels are then stitched together using rivets.

5. We imagined a continuous plywood surface that is stretched across the entire site like a sail or tensile fabric, leading the viewer from the low entrance to the 8m high glass curtain wall at the other end. We also wanted a structure that is lightweight and has as little framework as possible. We aimed to form a minimal surface contained within a series of arches that frame the entrances and connections to the rest and Xtra, the street and the adjacent café, and took reference from the soap film experiments of Frei Otto.

6. The knowledge gained in the experimentation process culminates in a 1:1 scaled model of a twisted wall to ceiling element. The full sized model allowed us to reaffirm the deviations over a longer distance and gave us crucial insights into the challenges faced during assembly.

Image Gallery

CREDITS

CLIENT: XTRA Design

PHOTOGRAPHY: Edward Hendricks, CI&A Photography

CARPENTERS: Xtra in-house and Song De Pte Ltd

METAL WORKS: Wah Chye Engineering Work and Hufcor Pte Ltd