WOODSCALES

COMPLETED

HERMAN MILLER @ XTRA SHOP-IN-SHOP

FUNCTION: Furniture Showroom

SIZE: 200 sqm

LOCATION: SINGAPORE, 9 Penang Rd, Park Mall, 238459

AWARD: 2012 World Architecture Festival.

Best Retail Building of the Year

Our design inspiration comes from Herman Miller’s core products; Work Chairs. Herman Miller’s extensive range of work chairs produced over the years embodies their philosophy, culture and aspirations; a desire to constantly innovate, integrate technology with design and produce high quality, purposeful, human-centred products.

The Herman Miller store is expressed as a porous plywood envelope forming an independent entity that plugs into the shop space of Xtra. This lightweight plywood grid shell structure formed simply by piecing together a series of modulated plywood panels, also, allows visual links yet maintains the identity of both stores.

Just as the Herman Miller work chairs are designed to adapt to our postures and movements, the Herman Miller skin is moulded to adapt to existing structures and customer movement patterns. The continuous surfaces forming the façade, walls, ceiling and entrances invite customers into the store and guide them through the experience.

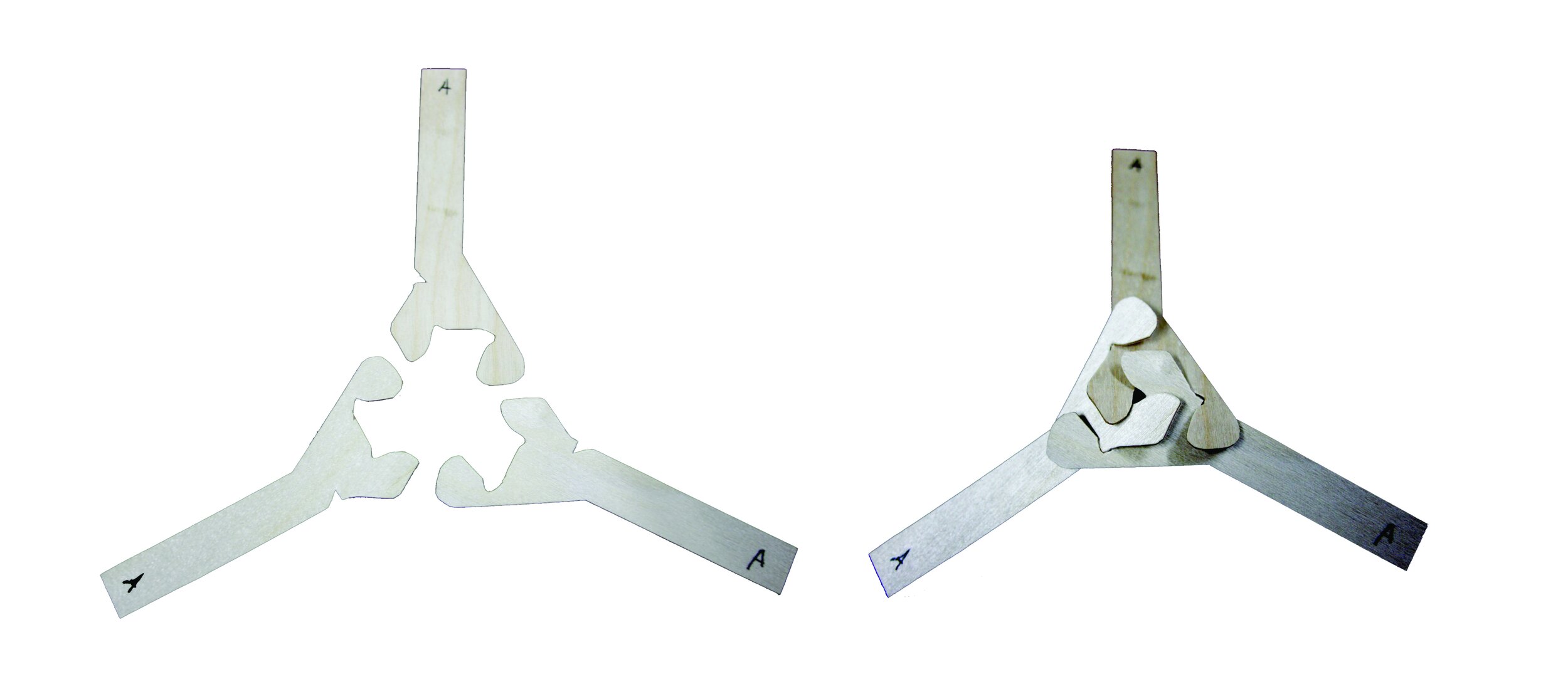

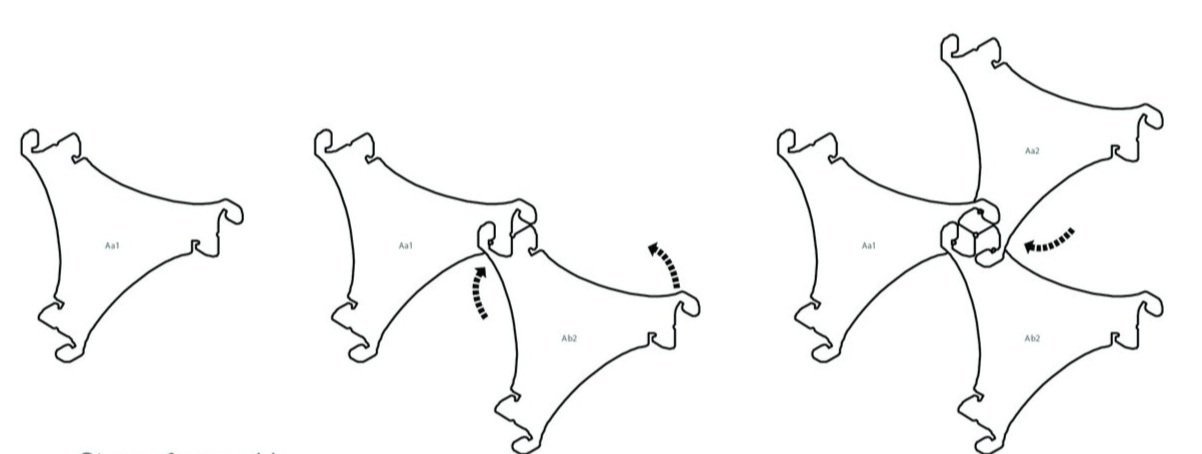

Designing the entire skin out of a kit of parts, demanded a certain ease in assembly. The complex envelope is pieced together using simple three-legged plywood component panels designed with interlocking lap-joints to attach modular panels together to form a larger surface. The components of the triangular grid shell were then applied on these base surfaces, and 3,651 panels are “stitched” together forming the rigid, woven double-layered envelope.

The majority of the panels are standardized to three varying sizes to achieve greater efficiency for fabrication and assembly. Customized panels are limited to the weaving as well as doubly-curved surfaces. There are approximately 4,000 wooden pieces that completes the whole design.

Compared with conventional design and construction techniques, the component-based design process demands a greater continuity and simultaneous planning across all stages of the project. From the design of the components and its joints, to the shaping of the envelope, to the fabrication of the panels and assembly on site, the entire process is controlled parametrically for increased accuracy and precision.

The result is a skin informed by Herman Miller’s philosophy that creates an identity inspired by their core body of work. The parametric surface modulates light and views into a flexible, open space. The plywood material forms a warm and casual ambience while its structure and assemblages expresses the dynamic process that combines technology with design.

Image Gallery

CREDITS

CLIENT: XTRA Design

PHOTOGRAPHY: FrameSG